Failures of SUNVIC motorised valves

including those with EcoSmart actuators (previously called SZM 1801 and SDM 1901) Unishare

valves also SZMV2305 (and spring return types 2301 and 2701 and variants). Also

DuoVal DM5601 and DM5651 Updated

March 2025.

REPAIR SERVICE for

Sunvic actuators.

Please note: this is an

occasional hobby, not a business! All sales and repairs are on a private basis.

I have repaired hundreds of Sunvic and other makes of actuators - primarily as one of my

hobbies and so that I could examine and photograph interesting failures. You can see many

examples on this website. I still have a few spare parts - you can always ask. I

offer a mail-order repair service for some types of actuators. This can include

replacing faulty micro-switches, which is a less common cause of failure, at least in Mo Mo

actuators.

For decades

I have undertaken all my own car repairs, building projects and plumbing and

electrical work, and for quite a few friends! One 'on site'

investigation of a very unusual plumbing problem is here.

I'm basically a physicist, author and building scientist - and I'm very

practical.

I have developed a modified design for 2-port Sunvic

Ecosmart/1801/1802/1808/1809 series actuators. These are suitable for use on a system

where the valve spindle is leaking a little - (this would be your own actuator modified to

my own design, provided the motor is OK) Price £100 - or more if other

components cannot be salvaged from your own actuator.. My modified units have

proved to be very

reliable. They avoid the expense of a drain down to replace the valve itself,

provided of course that your valve works and is free to rotate.

Please enquire via email stevewozniak42 (AT) hotmail.com. It may be a waste of money buying

another standard unit (even if you can find one) because it may fail after a short period. The same advice applies

to the 1901 3-port range but no 'redesigns' are available. One option here may be to use a

2701 unit to replace a 1901 but again there are now problems because in recent

years Sunvic have used a Korean motor instead of the ultra-reliable USA-made

motor that was an industry standard for decades. So I can no longer recommend

buying a new 2301 or 2701 unit. The same applies to some other makes of

actuators!

Also, as of mid 2021, Sunvic went out of business. For decades they were a UK

based company producing fine products. Then the rot set in with horribly

designed electronic actuators, poor quality control and more recently the switch

to Korean motors in their long established designs.

They resurfaced in 2022/3 and were seeking Distributors and Stockists.

Some very old-stock actuators are often for sale on eBay for very high prices -

and for products that are 40 and more years old!

Repair prices are as follows:

Two port valve actuators (including spring return 2301 types and variants) are

repaired for £18, three port types (1901) for £20 and spring return three port types

(SD2701 and variants) for £22. DuoVal DM 5601 and 5651 units and the similar two

port SM5203 types can also be repaired but as these are older designs they tend

to be very reliable. However, they do not use current industry standard wiring. Prices include return postage to the UK. For (Southern)

Ireland and Europe (France etc Zone 1) please add £10.00. This is to cover the

extra return postage to EU.

In all cases if a replacement motor is required there is an extra charge, but this is

quite rare alongside micro-switch and capacitor failure. In all cases, there is no return

of the inspection/test/repair fee if the actuator is not repairable - only a P&P

element (£4) is refundable, unless you want your irreparable actuator returned!

Most types of actuators are repairable because they only have 'standard' faults. Some

motor types are not available as new items but I may have a good used unit.

Contact details - stevewozniak42 (AT) hotmail.com

Occasionally I may have good used valve actuators for sale, please enquire.

These webpages deal primarily with modern Sunvic motor-on motor-off (MoMo) actuators

including the popular Unishare type.

To operate your system without the valve actuator in place can be a little daunting if

you are not experienced in electrical work and central heating. Some guidance on how to

operate simple systems without the valve actuators in place is given below. However.......

don't meddle with electricity unless you know what you are doing. You could kill yourself

or set fire to your home. Also, do not open any actuator unless you are competent to do

so.

Historical perspective:

In 2007 I became interested in why a range of Sunvic motorised valve actuators seemed

prone to very early failure. I had previously enjoyed a career as a scientist with much of

my work centred upon domestic and industrial heating and cooling systems. I knew from

personal experience that older designs of motorised actuators used in housing often worked

reliably for 20 or more years, yet the new 'improved' designs failed within a few months

or years. When writing up my findings I envisaged that what I had discovered would be of

interest to only a small number of technically minded people. In the event, this section

of my website has become perennially popular.

Initially, it was devoted only to the 'new' designs of actuators utilising electronics

in lieu of the more conventional spring return mechanisms and indeed the new designs did,

in theory, offer quite a few advantages. The webpages are now being reordered to

illustrate the most common faults not only in the new designs but in those that have

remained substantially unchanged for decades. Some evidence has been collated showing the

degree to which the micro-switches often used within motorised actuators may overheat and

the propensity of the circuit boards within the 'new' Sunvic designs to explode. To my

knowledge no house fires or similar events have resulted from a failed motorised actuator.

A page of photos showing common problems is now available.

A recent addition to the market, a few years ago now, is the Sunvic SZMV2305 - internally it looks almost

identical to the 1801. It has a different make of microswitch - but these very rarely gave

problems anyway. The reason for adopting a new part number is therefore unclear - maybe it

is just an effort to distance the design from bad publicity surrounding types 1801 and

1901.

I have had personal experience of the explosion of a circuit board from a failed 1901

unit - this occurred when the unit was connected under test, having been sent to me for

examination, having already blown a boiler system fuse. The flash was quite spectacular

and accompanied by a large 'bang' - and this with the circuit board having had

several days to dry out whilst in the post and stored at my home. This second explosion

(following the first which blew the system fuse) serves to emphasise the importance of

always operating Sunvic 1801/1901 units with their protective covers in place. The

photographs are at the bottom of this page.

The new page includes:

- faults inherent in the Sunvic range of MoMo

(motor on motor off) actuators of types 1801 and 1901 and variants,

- faults within the popular 2301 and 2701

series of spring return actuators

- examples of severe overheating of

microswitches in both Sunvic and other types of actuators.

ACL (DRAYTON) motorised mid-position

actuators especially type MA1 (often type MA1/679-3) and similar types as shown in this

photo usually fail owing to a very small and unusual internal microswitch burning out.

This can be replaced, please enquire.

|

More photos are here.

Email address: stevewozniak42 AT hotmail

DOT com

These actuators can usually be repaired. |

So predictable seem to be the failures of

some Sunvic actuators that their design may be called a minor environmental disaster. Tens

of thousands were probably manufactured, all may fail within a few years (some within

18 months) and most will be scrapped by plumbers who simply fit replacement units. If

properly designed, valve actuators should last 20 to 30 years - as Sunvic/Satchwell

Minivals used to do. An increasing number of failures are now being seen where the circuit

boards have exploded. The reason is that the 1801/1901 range of 'electronic' actuators

have proven to be extremely sensitive to even the slightest water ingress via leaking

valve spindles and the circuit boards were very poorly designed. Older designs of actuators are

unaffected by slight leakage, as is further explained below.

This section of the SeeRed website details why Sunvic motorised central heating valve actuators of a

particular design often fail to operate correctly. The main text applies to both modern

two-port and three-port (unishare) valves. These all have a similar design of electronic

circuit and regularly fail in a similar manner. These valves are not sold only under the

Sunvic name. For example, they are found in expensive Worcester-Bosch systems, as

this email has highlighted. These 'badged' actuators are also sold at curiously high

prices.

The popular Unishare three port valves are particularly prone to failure but can

usually be repaired quite easily. The two port designs simply fail to open reliably a few

months before they fail completely. Again, repair is usually straightforward. Spring

return valves (typically Sunvic 2301 and 2701 types and many variants of the same basic

design) can also often be repaired.

Fortunately, it is not usually necessary to drain the heating system to effect repairs

- all that needs to be removed is the valve actuator.

Failure can lead to low room or domestic hot water (DHW) temperatures. This in turn can

lead to other components such as thermostats and programmers being suspected of being

faulty. Hundreds of pounds are sometimes wasted in replacing components unnecessarily.

More seriously, faulty central heating controls can leave elderly people vulnerable to

the cold. Failure of these Sunvic actuators may be expected to be intermittent, at least

for several months if not longer, as electronic components gradually degrade. Old people

may not be believed when they complain about being cold - because when relatives or health

visitors call, the heating system may be working satisfactorily again.

A less common fault in Unishare three-port valves can lead to excessive hot water

temperatures - sometimes the motors run backwards! This is owing to gearbox grease

becoming 'sticky' with age and heat, and this is usually followed by complete actuator

failure - photos are on this supplementary webpage.

Again, it is a problem that should not occur, and especially not after only a year or so

of operation.

Supply of spare parts for Sunvic

motorised valve actuators. Updated March 2025.

I have a few spares available. Capacitors

for MoMo valves (1801, 1901 and similar types) can be supplied for £2.00 each, plus a

P&P charge of £1.50 (to UK) - so one capacitor will cost you £3.50

and two will cost you £5.50. Except for zener diodes and a few

microswitches, NO OTHER SPARE PARTS ARE USUALLY AVAILABLE. I may sometimes have a

second-hand part available if your actuator has an unusual fault.

I have never routinely sold the microswitches needed to mend many of these valves

because proper testing can be necessary to establish whether the switch needs replacement.

In particular, the internal circuitry of the SD2701 and related 3 port designs is quite

complicated and many faults stem from sticking motors and gearboxes. Two port 2301 and

similar types are simpler. Both types are prone to microswitch failure but usually only

after many years' service. It is often not worth mending a 2701 with multiple failed

parts.

For 1801/1901 and similar MoMo types, the capacitors must be X2 rated of a similar spec

to the originals. They will be 330 nF rather than the 220 nF that Sunvic used in earlier

batches of actuators - before they discovered that many of their actuators were failing so

prematurely. Be aware when fitting these that the old units may have retained some charge

- therefore discharge them before unsoldering. Also, if repairing an early valve with a

220nF capacitor, you will need to fit a 3.25 watt 24 volt zener diode to limit the relay

coil voltage if you fit a 330nF replacement. If you just want a 220nF capacitor I

have a few of these (same prices as above) - the actuator will operate reliably for less

time but no extra diode is required. In 2013/14 it was suggested that

widespread premature failures of X2 rated capacitors as used by Sunvic may have been owing

at least in part to poor quality manufacture of the capacitors themselves. A report from

ERA is available.

Note that capacitor failure here is quite different from that described on

this webpage - where the co-called Capacitor Plague of 2002 to 2010 is

discussed. These and similar problems with electrolytic capacitors affected (and

still affect) televisions, toasters, monitors, computers and other electronic

equipment including where switched mode power supplies are used (which these

days, is virtually everywhere!). The failures of the X2 capacitors in some

Sunvic and similar actuators is the result of appallingly bad basic circuit

design.

In purchasing spare parts you MUST be aware that repair of these valve actuators

is (of course) not recommended by Sunvic. However, for anyone well versed in soldering of

electronic components, DIY repair is a feasible proposition, provided you are wholly

competent in dealing with mains electricity and hobby electronics. If you don't meet these

criteria then get someone who is a 'competent person' to remove the actuator for you and

make the system safe.

Sometimes, the zener diodes that are connected across the relay coils have been found

to be almost 'short circuit' - in this case the DC voltage across the relay coils may be

as low as 0.2 - instead of 24. Failure of the smoothing capacitor (which sometimes goes

with failure of the rectifier) can be a factor also, but this is uncommon.

In one actuator I mended in December 2010 there was a most unusual fault - a high

voltage flashover had blown the relay coil and fried one half of the rectifier bridge. In

essence, a high voltage pulse had arced across from the thermostat wire to the low voltage

relay coil and returned to earth via one half of the rectifier bridge. I actually bothered

to clean up the pcb and renew all the components. The actuator was returned to a bemused

householder - who was left with the unsolved problem of why his heating system routinely

tripped out circuit breakers. In later years, the issue of exploding circuit boards became

more common as more and more valve spindles started to leak very slightly. In these cases,

for 1801 actuators, a new design can overcome the problem (see top of page). No such easy

option exists for the 1901 three port design.

All legal liability for any incompetent repair rests solely with the person who

undertook the repair. If you don't know what you are doing, then don't do it! Organisations

such as CORGI (now GAS SAFE) say that only 'competent persons' should ever try and mend a

heating system. In my experience, many of their so called 'qualified engineers' should

never have been let out of school, so poor is both their knowledge and workmanship.

Against that, many DIY repairs to houses are appalling!

It may be noted that the Sunvic company failed to respond to emails questioning the

reliability of products that were described in Sunvic sales literature as being very

reliable. Unishare three port (mixer) valves can fail in under three years - I have

repaired some that are between 1 and 2 years old. There is a good

technical reason why these popular Unishare valves are proving to be even less

reliable than their two-port alternatives.

An advertisement for poor design. I now have hundreds of these! |

It is curious that even in 2008

and indeed also in 2010 and beyond, Sunvic were still apparently telling customers who

complained that they 'have had no complaints about these actuators' and are not aware of

any design faults. The original design dates to around 2001/2 but as early as 2003/4

Sunvic had changed the design to incorporate a larger capacitor and a zener diode.

The only reason for undertaking this design change would be to try to prolong the life of

the actuators before (premature) failure occurred. As it happens, the design modification

seems not to have improved matters very much, especially for the Unishare actuators.Here

are some failed capacitors, together with a couple of faulty microswitches. Probably

thousands of actuators are simply thrown away by plumbers. Sunvic have used capacitors

made by at least two major manufacturers. Both types seem to fail in the same way - so a

specific design or manufacturing problem seems to be ruled out. However the

problem may be related to inadequate capacitors as well as to problems with circuit

design, such as absence of a series resistor. |

Important safety notice: Motorised valves will most often be found as a

component of traditional central heating systems that include a hot water cylinder.

Increasingly, combination boilers are being used - especially in smaller houses and flats

- and these are both more complex and more potentially dangerous. Never alter any part of

a combination boiler system or a pressurised hot water system without seeking advice. The

usual use for motorised valves with a combination boiler will be for zoning of a large

central heating system (and using two-port valves). These can readily be operated without

the actuators in place.

Whilst repairing some types of Sunvic valve

actuators (and many other makes) is an easy job for anyone versed in electronics,

inexperienced people should not attempt this work. Some skill in soldering is required -

and remember these are mains operated devices. The usual precautions should be taken when

removing a unit from the mains wiring - including switching off the isolating switch-fuse

that should control the entire heating system and removing the fuse. In addition, check

that the system really is 'dead' after removing the fuse - I have known houses in which

live and neutral lines have been reversed even at the main distribution board (fusebox)!

Also, remember to make a careful note of which colour wire goes where - and if you are

removing two valve actuators, which wire from each actuator goes where! Do NOT attempt

this work unless you are experienced with mains wiring. With systems using two two-port

valves (usually, one for central heating, the other for domestic hot water control), you

may find that two orange wires, one from each valve actuator, are joined together - this

is normal. The two grey wires may also be joined (again one from each actuator) - these

are permanent live feeds to the two-port actuators, similarly the two blue wires (mains

neutrals). The two brown wires must be replaced in their correct positions - or you will

end up with the central heating controlling the dhw and vice-versa. Typical wiring

diagrams are shown in the Sunvic catalogue

(750k pdf file, allow time to download) - the diagrams are on page 17. Be sure to study

the right one!

The wiring of many central heating systems in the UK is undertaken to an appalling

standard (typical of the UK building and plumbing industries) so be prepared to find

shoddy work that needs rectifying. For example, it is quite common to find three port

valves wired up without a cylinder thermostat. It is all too common to find systems fitted

without a bypass loop and in system designs where one should have been fitted.

TWO PORT ACTUATORS: operating a

heating system without an actuator in place.

If removing a two port valve actuator, the

central heating can be left in operation by turning the valve spindle to the 'on' position

and using the time-switch or programmer to control room temperature in a crude manner.

However, it is also necessary to 'con' the boiler into thinking the valve actuator is

still in place and ordering heat. This can be done by temporally linking together

junctions within the wiring centre of the heating system - but again this may be fraught

with problems because (in my experience) so many are wired to a poor standard. Non-technical householders should not attempt this

work themselves. It is a matter of

linking together the two

terminals to which the BROWN and

ORANGE wires of the valve actuator were originally connected, if the thermostat is a type

that can handle the pump current directly. This has the effect of telling the boiler

electronics that the system is asking for heat. If you want to control the system

manually, link the terminals to which the ORANGE and permanent live (GREY) wires

were connected and simply switch the boiler on and off as required at the isolator switch.

This avoids possibly overloading the thermostat (BROWN wire).

The way two-port actuators work is as

follows: The BROWN wire supplies live (240 volts) from the relevant thermostat to command

the valve to open when the thermostat requests heat. The valve actuator should respond by

opening the valve and then signalling to the boiler and pump to switch on - it does this

by supplying 240 volts (live) to the ORANGE wire, taking this live supply from the

GREY wire.

If the Sunvic valve actuator controlling the dhw supply has also failed the dhw can of

course be operated also but the stored water temperature will approach that of the main

boiler thermostat (because the valve will no longer be controlled via the cylinder stat).

In these cases, to avoid the risk from scalding, turn down the main boiler thermostat to

about 55-60C. The valve can be closed manually whenever it is desired to stop heating the

DHW. All these procedures require some knowledge and competence and, once again, do not

meddle unless you understand what you are doing.

If the boiler and plumbing has been installed correctly (famous last words for the UK

plumbing industry!) and with a bypass loop, there should be no problem in closing both dhw

and ch valves manually if you wish to control the system in this way - the boiler will

then cut out on its own thermostat(s) (which it may do anyway during normal operation with

a light heating load) and the pump should run until excess heat has been dissipated via

the bypass loop. Again, there are many examples of poorly installed plumbing systems in

the UK, so ask an expert (if you can find one) to check if you are in any doubt about

operating your system without the valve actuators in place.

Three port valves:

Three-port valves operate in a similar manner but the wiring is different and some

valves are never installed properly by builders and plumbers in the UK. Some other types

of three-port valves (not the Sunvic type discussed here) are quite complicated

internally.

To operate the system without a three port actuator in place can sometimes be

accomplished by very carefully turning the spindle of the three port valve a little bit with a small pair of locking (molegrip) pliers and wedging it in an open

position. In its 'closed' position it will supply only dhw and the system should work

without the actuator in place at all - because none of the internal circuitry is utilised

for dhw-only operation.

Supplying 'live' to where the orange wire from the valve was connected generally

enables the boiler to light up and the pump to operate whatever type of valve has been

fitted, but there are issues of how hot each circuit will get if it is not properly

controlled - so turn down the main boiler thermostat to about 55-60C. Generally the orange

wire is made live within three port valve circuits when CH is required and the actuator is

instructing the system to provide central heating. It is made live for dhw via the

cylinder thermostat. But remember - don't meddle with electricity unless you know what you

are doing. You could kill yourself.

My personal recommendation for standard domestic heating systems has always been to use

two two-port valves, rather than one three-port valve. The much older design of Satchwell

Sunvic 'Minival' two-port motorised valves were renowned for their long trouble-free life

- I have some that are 30 years old and they are still working. Again, the appropriate

wiring diagrams are given in the Sunvic catalogue.

A common cause of failure is that the valves become stiff and this overloads the drive

gears in the actuator. The drive spindle of 2 port minivals should be free enough to be

turned around using only fingers. If it is not, try rotating it many times in either

direction using pliers. This can 'free off' scale inside the valve.

|

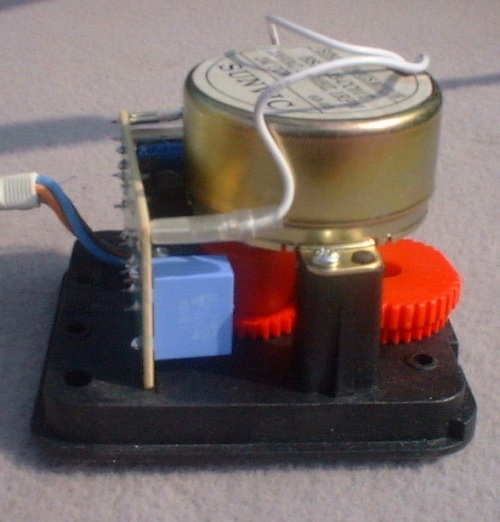

A view of the motor

unit SZM 1801 as used on a Sunvic two-port valve. Similar problems occur within Sunvic

three-port Unishare actuators. Indeed, the Unishare design is even more prone to early

failure than are two-port designs. Similar motor control electronics is used within

three-port Unishare valves, but some of the components are 'live' for longer, and so fail

sooner. This is disappointing because the basic design that lay behind

this innovative range of valves is sound - they are a direct wire-in replacement for

spring return valves that are a common feature of many domestic central heating circuits.

Spring return valves can fail via motor burn-out because the motors are energised all the

time the valve is required to be open - but they generally last much longer than these

newer Sunvic designs!

You can easily tell if a Sunvic valve of this type is 'open' or 'closed'. Just

look for the 'flat' on the red gear wheel - a good design feature. With Unishare valves,

the flat denotes the mid (mixed) position.

Removing the actuator head (the part shown here) could not be simpler - just

follow the instructions on the Sunvic leaflet (click here) |

|

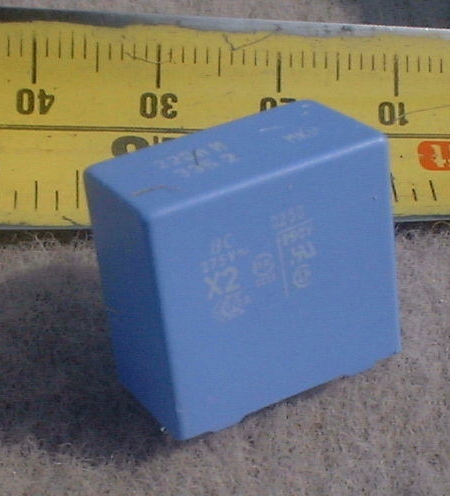

The motor unit of a

two-port valve: gear wheels (red) and the light blue capacitor which has proven to give

problems. This is X2 rated and replacements MUST be of a similar specification. X2

capacitors are usually used for suppression of high frequency voltage peaks across 240 VAC

lines. They are often used in situations where failure of the capacitor might cause a fire

- these capacitors are designed to fail-safe, although some problems apparently still

occur because their inherent self-healing characteristics can become compromised.

Where failure of a capacitor would lead directly to an electrical shock hazard

then an even higher specification Y class capacitor must be specified.

Failure of a microswitch can lead to these motors running for hours instead of

for a few tens of seconds. They then overheat and burn out. Sometimes hot grease leaks out

and jams up both microswitches! This is one of the more unusual modes of failure for these

supposedly reliable devices.

Gearboxes also fail - see below. |

|

View of the two

microswitches that are operated by the red gearwheels. The electrical relay is on the left

- it is a 24VDC type which needs at least 17 to 18 volts to operate reliably. When the

large capacitor begins to degrade, the available operating voltage drops below that

necessary for reliable switch-on, hence the valves exhibit all the symptoms referred to in

my emails to Sunvic. I first suspected that either the microswitches or the relay itself

was at fault. The equivalent three-port designs are more complicated

having two relays and two sets of C1/C2 capacitors and rectifiers, three microswitches but

only one motor - all quite clever!

Repair and testing are not typical DIY jobs. More details of three port circuit boards and

their problems are here. |

|

This is the component

that causes most of the trouble. The circuits used in these actuators are arguably a

poor design because partial failure of either of the two capacitors (or both of them) can

lead to a lower than acceptable DC voltages. This is a 220 nF unit from an early valve

(late 2003). One of the mysteries is why Sunvic used a DC relay

especially for the two-port design. Using a more expensive AC relay would have avoided all

the problems. There may be good reasons why the circuit was designed with a DC relay. Except maybe - that in the Unishare design - using ac relays

would have imposed significant cost and size disadvantages on the finished product. Low

profile relays of the type employed simply do not seem to be available with 240vac coils.

Safety note: whilst replacing these

capacitors is a trivial job for anyone versed in electronics, inexperienced people should

not attempt this. Some skill in soldering is required - and remember this is a mains

operated device.

Replacement capacitors MUST have an X2 rating with a 275VAC working voltage. |

|

The zener diode fitted

in modern Sunvic valve actuators to limit back emf produced by switching off of the relay

coil - and to limit forward voltage. This modification (shown rather poorly soldered in

this example) may have been introduced by Sunvic in response to early valve failures

examined under warranty. Ideally, a diode would have been incorporated

into the pcb design: this 'afterthought' is hardly an advertisement for quality

manufacturing.

Other diodes found in these actuators are physically smaller and are BZX 24

volt types. If the diode fails the coil voltage may rise to about 30 - which may not be

too serious - or may drop to 0.2V - which stops the unit working at all. |

|

A 330nF capacitor is

fitted to modern actuators. Replacing a microswitch must be done very

carefully and using a type exactly equivalent to the original - with a 3 or 5amp 250 VAC

rating.

In one Unishare actuator I tested, a 330nF capacitor was so degraded the relay

voltage was only 9.8 - and the unit was less than 3 years old! In another, it was 12 volts

after only 15 months.

Sunvic appear to have changed the capacitors to 330nF to try to avoid premature

failures but to little avail - because whole idea of using X2 capacitors to drop mains

voltage may be suspect: a particular problem may be high temperatures of operation and

frequency of thermal cycling. Another

problem (highlighted in 2013/14) may be poor quality capacitors, and this seems to have

affected many electronics manufacturers.

It is interesting that most plug-in digital timers use an X2 capacitor to drop

mains voltage. It is a cheap way to produce low voltage DC if only a low current is

required. These units may have a larger zener diode and be more able to tolerate

degradation of the capacitor. The electronics may also be supplied via a voltage regulator

- so reductions in the basic VDC output may not matter too much. |

|

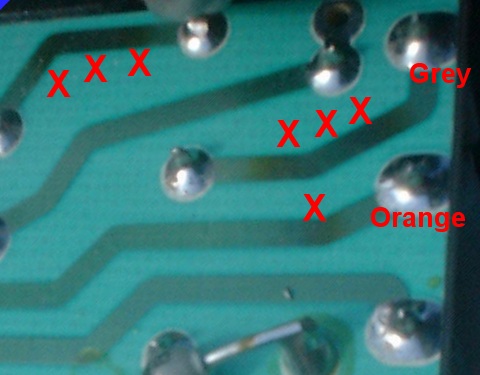

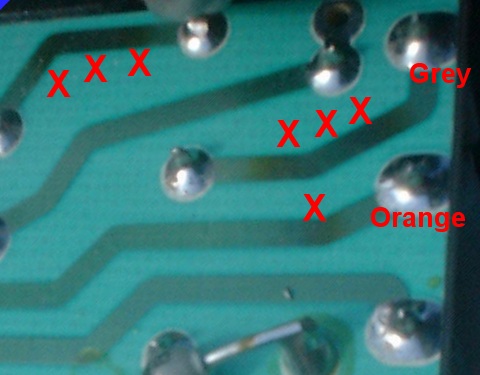

Overheating of PCB

tracks in a Sunvic actuator that failed because of a microswitch in which the points had

become welded together. This failure was caused by excess current: a

warm air system heater had been incorrectly wired with full fan current passing through

the valve actuator. A wiring fault of this type could result in a house fire - so if a

component fails in this manner, find out exactly why!

The tell-tale overheating and incipient blistering of the tracks (shown as XXX) is most pronounced on the track connected to the grey wire - which takes

the mains live supply into the valve circuits.

Discoloration of the track connected to the orange wire was slightly less

pronounced. |

|

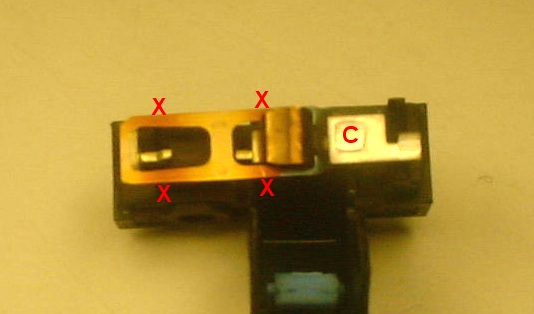

The inside of a

microswitch that had failed (with contact points welded together). The cause was

electrical overloading owing to a fault in a warm air heating system. A 3 amp fuse is usually specified for the isolator

of a conventional domestic wet central heating system. The contacts are underneath C.

Discoloration at regions X

bear witness to overheating.

If the contact points were the cause of the overheating (because of high

contact resistance) then discoloration would be expected primarily close to the points -

yet here it is just as bad on the left hand side. This suggests excess system current as

the primary cause of actuator failure. |

|

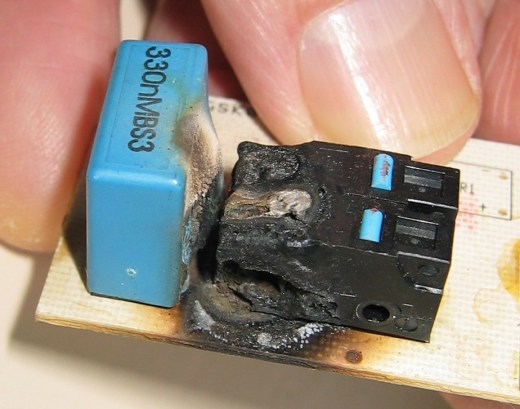

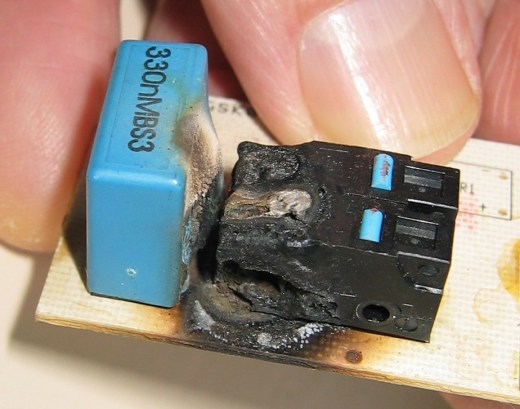

In this case however,

the circuit board has failed in a spectacular fashion, melting both micro-switches and

rupturing the 330nF capacitor. Although the reverse side of the pcb is

badly burned in the immediate locality of the switches, the tracks elsewhere are not

discoloured, and the system was fused at 3 amps. Excessive current is therefore an

unlikely cause of the failure.

In this example therefore, failure was likely owing to a high resistance

contact in one of the micro-switches - leading to localised overheating.

Similar problems are sometimes found within domestic 13 amp wall sockets as

well as (quite commonly) in Sunvic 2301 and 2701 actuators. |

|

In this example, the

relay points and push-on connectors have overheated. This illustrates why actuators have

heat resistant housings. The temperature that was attained was enough to melt and burn PVC

and to char the relay casing and pcb - yet probably a house fire was unlikely. Despite

that such pieces of 'domestic electronics' may pose a low fire hazard it is maybe not a

good idea to smother them in blankets - as can happen inside airing cupboards.

It is surprising that this actuator did not go 'open circuit' and stop passing

current before the overheating became so extensive - but current would cease only when one

of the wires or contacts had completely oxidised or melted.

Moral of the story: never ignore a strange smell of burning from your airing

cupboard, or from under the floorboards!

This all shows the consequences of poor basic design - including perhaps tens

of thousands of repairable Sunvic actuators being scrapped.

Photographs of Unishare actuators that failed because of water leaking from a valve

spindle seal and because of poor quality control are shown on another page (click this link). In both cases,

short circuiting of high voltage to low voltage areas on the pcb caused components to

explode.

These and similar cases are not 'isolated incidences' - they are quite common. |

The full wiring circuits for two-port and

three-port valves are included in the following pdf page. This is taken from the patent website

describing these Sunvic valves.

pdf diagrams of wiring in Sunvic valves (use the zoom feature

of Acrobat to view the lower diagram clearly)

Also available is the installation leaflet for Sunvic SZMV

series valves and SZM 1801 actuators - strangely it states that it should not be left

with the user - yet these motorised valves used to be sold by B&Q and other

do-it-yourself superstores direct to end users! This leaflet includes the basic wiring

diagrams needed by installers.

Other companies in the plumbing industry are more open about their products - for

example, Triton showers are often easy to mend because parts can be ordered direct from

their website. However, like so many UK companies, Triton are increasingly buying in

components made in China or elsewhere overseas and no small spare parts are available -

only complete assemblies. I once had to mend a flow stabiliser valve in an electric

shower. All I needed was a simple 'O' ring to replace one that had perished. Triton

offered to supply a complete valve for £40. I used an O ring of slightly the wrong size

and it has worked perfectly for over ten years. 'Make-do and mend' has a lot to recommend it - but only if you

know what you are doing!

detailed explanation of failure of Sunvic MoMo

valves

why Unishare three port MoMo valves are less reliable

than equivalent two-port valves

water damage to the electronics of a Unishare

1901 actuator

photos of motor and gearbox failures in modern

Sunvic valves

home page