Whilst there are many part numbers, many types (and going back at least 10 years) are substantially the same inside.

On the left is an ACL mid position actuator and valve assembly probably over ten years old. On the right is a modern (2011) Drayton MA1 actuator.

Whilst modern actuators can be removed from the valve body in a couple of seconds and replaced if necessary, older units need to be completely stripped down in order to separate the actuator from the valve. These used therefore to be replaced as a complete assembly. However, separating an older type of actuator from its valve can be done 'in situ' if you have enough working room. The actuator might then be repaired without draining down the heating system.

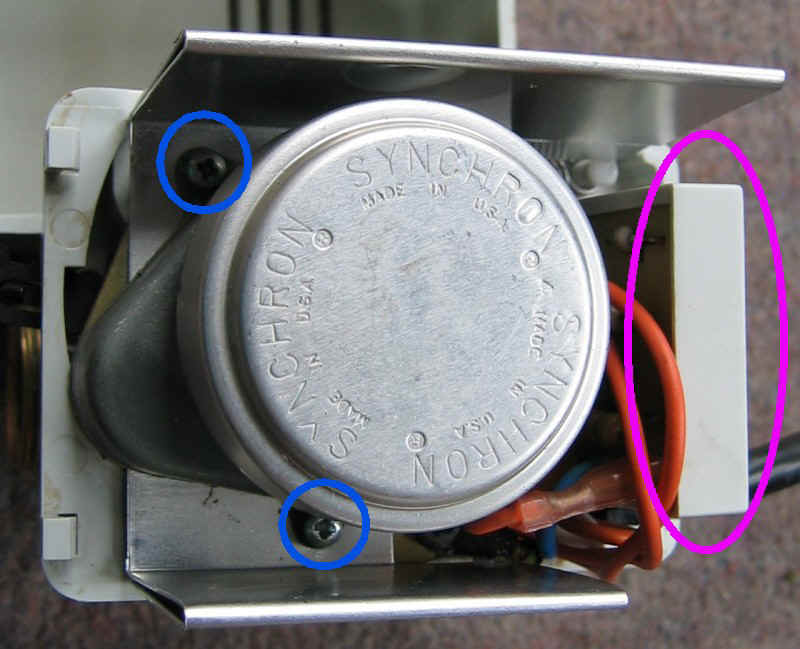

These units typically use an 'industry standard' Synchron motor - these have been made in the USA for decades. Cheap copies are now available and are often sold as 'Synchron' or 'Synchronous' motors on ebay and elsewhere for around £8. Genuine Synchron motors can often be obtained for about £15 - and are of guaranteed quality.

A typical life can be in excess of 10 years. These motors are used by many manufacturers of spring return motorised valve actuators.

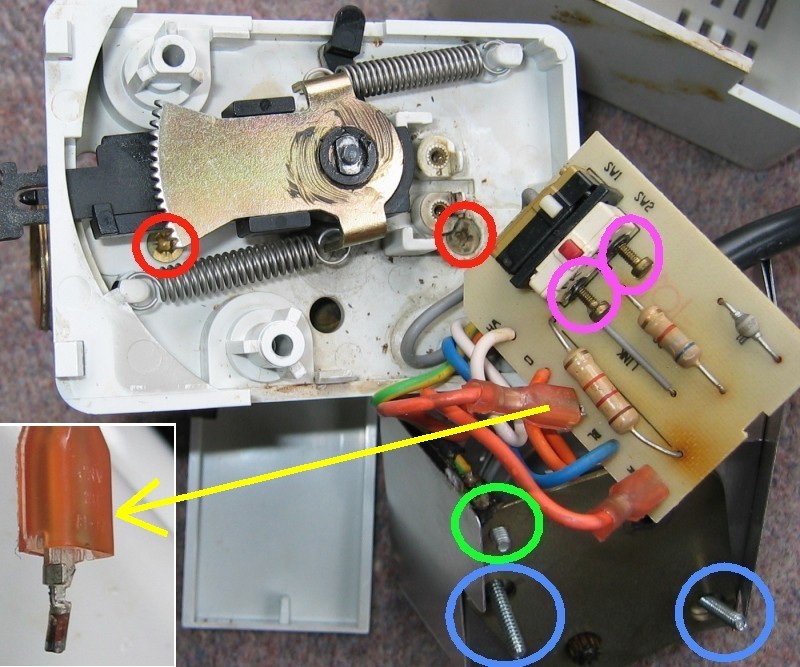

In more modern actuators, the circuit board is a tight 'press fit' into retaining lugs and is much less easily removed. However the basic design, and including use of an unusual and tiny two pole microswitch (SW2), is substantially unchanged.

Switch SW1 is a much more common type and is used in many Sunvic actuators also (for example 2301, 2701 and variants).

The actuator can now finally be removed from the valve body by unscrewing the two brass screws circled in red.

Faults in these actuators may be expected to mirror some of those found in Sunvic designs, for example, motor gearboxes may become stiff with age, motors may burn out, and microswitches may fail and sometimes melt and overheat owing to current passing through a high contact resistance.

In this unit, the lower motor connection (yellow arrow and shown inset) simply pulled out of the circuit board - maybe owing to having been twisted a little during dismantling.

Modern valves have the same general pattern but new and old type valve bodies and actuators cannot be interchanged.

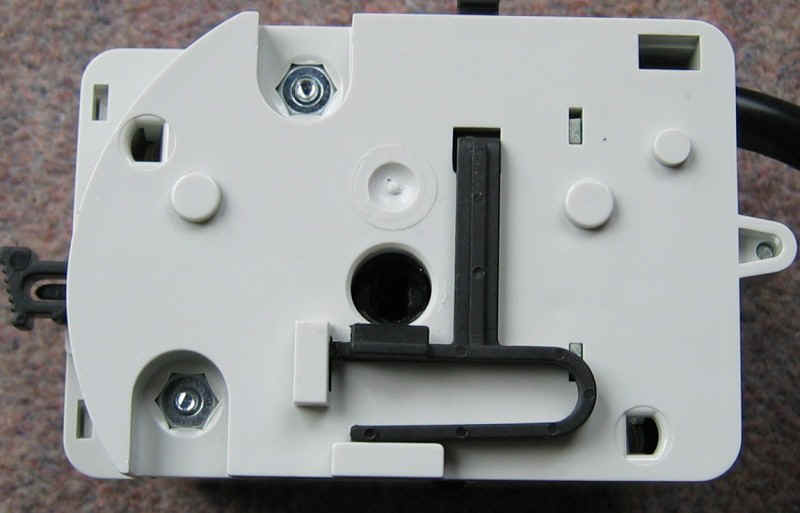

Because the central spindle is offset from the centre line of the locating lugs, the actuator cannot be fitted incorrectly. This is a good design feature.

The parent company is nowadays Invensys of Plymouth, UK.