The matching front discs were in a similar box, but made in GB, not D (Germany?).

Problems with LOCKHEED Delphi replacement rear discs (in the USA: rotors) for a Saab 900i (1992 model) purchased from Hilsmith Ltd (trading as British Car Parts of Tiverton) and via an ebay advertisement.

The photos below explain what I believe to be a design/manufacturing fault on replacement rear discs I purchased from British Car Parts of Tiverton (Devon) in July 2012. I tried to fit them in September 2012 - the front discs and pads that I purchased at the same time fitted perfectly, but the rear ones would not seat correctly onto the rear hubs. These discs (if incorrectly machined or indeed fake products) may be dangerous if fitted to other similar Saab 900 or 9000 vehicles. Any advice from automotive engineers would be welcome - surely the Lockheed discs are incorrectly machined?

|

The label from the box of

suspect brake discs - the type number is BG2420 - manufactured by Lockheed Delphi. The matching front discs were in a similar box, but made in GB, not D (Germany?). |

|

A close up photo showing the

skew of the new brake disc when the disc locating screw was tightened at the opposite side

of the disc - this end has 'tipped out' and the disc face is no longer parallel that of

the hub.If an attempt were made to insert and tighten a wheel bolt, the disc here would be

badly warped and/or subject to large stresses that it was never designed to accommodate.

The VISA receipt is shown below.

|

|

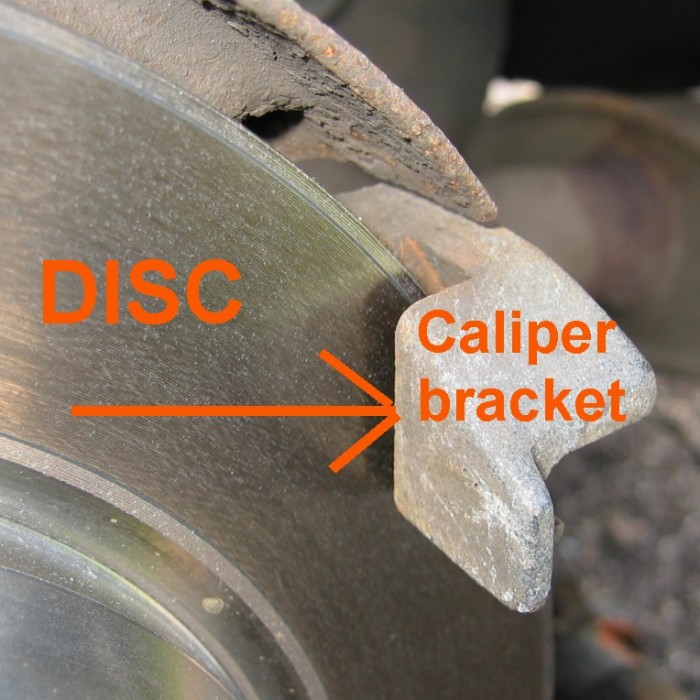

The new disc fitted with its

securing screw hand tight - it skews over to one edge and thus there is a large clearance

between the disc surface and the rear brake caliper mounting casting. If the brake disc is now rotated through 180 degrees the gap disappears - see picture below! |

|

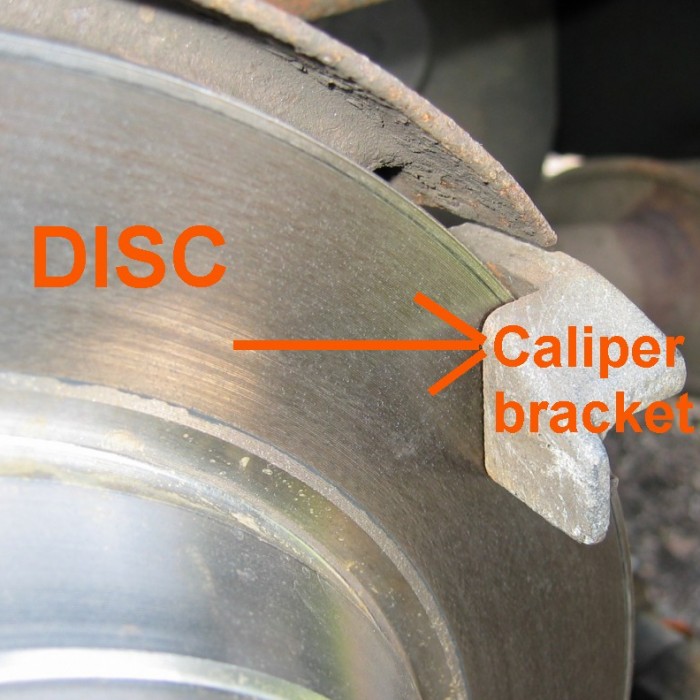

With the brake disc rotated

through 180 degrees it now catches on the outboard surface of the caliper mounting

casting. There is now zero clearance between the disc and the casting. If an attempt were made to fit the wheels using conventional methods (tightening one bolt first then the rest), there might be a risk of damage to the internal components of the brake caliper because of skewing of the caliper. The rear calipers on post-1988 Saab 900s contain the handbrake and self-adjust mechanisms (earlier cars incorporate the handbrake mechanism inside the front calipers, a design that proved disastrous in itself!). Once set, the pistons cannot be forced back into their bores without damaging internal components. This may happen if a wheel were to be tightened up after the self adjust mechanism had been reset as a part of installing new brake pads: this procedure involves using a 4mm Allan key wrench to adjust the internal screwed components inside the hydraulic caliper. |

|

The new Lockheed discs. A close-up of the area circled in orange is shown below. |

|

Close up photos of the new

(left) and original (right) discs. The critical difference is that the outer raised area on the original Saab discs extends right to the edge of the wheel mounting holes whereas on the new Lockheed Delphi discs it does not - and furthermore there is a chamfered area before the (narrower) outer raised lip.

|

|

The original Saab discs. The consequence of the slight design change (or error in machining) is that the hub (which is perfectly flat) contacts the old discs (shown here) around both the inner and outer raised lips, and therefore the disc will be firmly located on the hub around its entire outer circumference as well as around the inner raised lip. Any one wheel stud could be tightened fully by hand or by light use of a wrench and the disc would not skew in any direction. However, the hub only contacts the new discs around the inner raised area - so if either the disc locating screw is tightened or a single wheel nut is screwed in even hand tight, the discs will skew markedly over to one side, making proper and true alignment of disc and hub impossible - even if the other wheel bolts are fully tightened. |

|

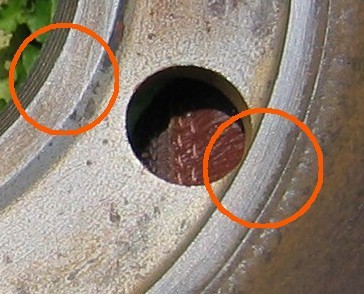

The rear hub of a Saab 900

Classic has a completely flat surface. The marks highlighted in orange show where the

original brake discs were in contact around both their inner and outer raised areas. The critical difference is that the original brake discs contacted the hub around its outer edge (just outside the bolt holes) whereas the new brake discs had no contact at all with the hub around this outer circumference. |

|

Saab steel wheels (this one is

from a 9000 model but fits the 900 also) are designed to locate around inner and outer

diameters. These are shown as the circles of rust. When the wheel bolts are tightened the entire wheel acts as a gigantic 'spring washer' with the areas of the wheel immediately below the tapered wheel studs being deflected slightly towards the hub. Alloy wheels are typically thick and have a flat mounting surface - they therefore have no 'spring washer' effect and so are more likely to vibrate loose - which is exactly what happens to alloy wheels on some models of caravans! The 'feel' of tightening steel and alloy wheels can be quite different - steel wheels exhibit a gradually increasing resistance to torque whereas alloy wheels exhibit a sudden resistance to any further rotation of the stud as torque is increased. Where suspension systems are quite firm and transmit road shocks direct to the wheels, only pressed steel wheels may therefore be reliable. Caravans and trailers with 'hard' suspension should perhaps only use pressed steel wheels. |